3-Axis vs. 5-Axis CNC Machines: Which One Is Better?

CNC machines have become more prevalent in the majority of manufacturing industries. These machines utilize computer numerical control (CNC) technology to automate manufacturing procedures, including turning, cutting, drilling, and milling. The exact and accurate operation of CNC machines makes producing intricate designs and components possible. Although numerous CNC machines exist, most fall into the 3-axis or 5-axis classifications. Their respective axes of motion capabilities are dissimilar. This article will contrast 5-axis CNC machines with 3-axis CNC machines. Borui CNC will give you more information.

What Is CNC?

“computer numerical control” (CNC) refers to using computers to control how machines make things. Most CNC machines execute operations like manual machining devices, but a computer program controls them. It generally results in parts of higher quality than those produced with manual drill presses, lathes, and so forth due to the exact movements of the cutting instrument.

What Is a 3-Axis CNC?

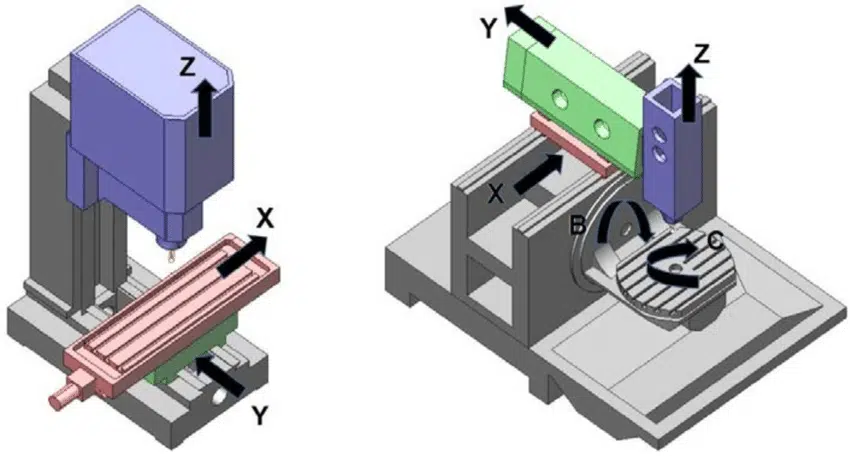

A 3-axis CNC machine moves its tool or component along the X, Y, and Z axes to execute machining operations. By adjusting its position along the horizontal (X-Y) axis, the cutting instrument can section components to predetermined depths (Z-axis motion).

What Can a 3-Axis CNC Do?

In addition to milling, drilling, and cutting, a standard 3-axis CNC machine can perform various machining operations. As for the others, they are CNC lathes. The machine is subject to certain limitations about part complexity due to the restrictions imposed by those three axes. The most effective three-axis machines manufacture components with simple geometries and few design or detail specifications. Parts with a 2D or 2.5D profile are optimal targets for 3-axis CNC machines.

What Are the Advantages of 3-Axis CNC?

Below is a list of the benefits associated with 3-axis CNC machines:

- Easy to use: Acquiring proficiency in operating 3-axis CNC machines is a breeze. It does not necessitate extensive operator training.

- Less expensive: 3-axis CNC machines are considerably cheaper than their higher-axis.

- Minimal Maintenance: The ease of use and design of these devices contribute to their low maintenance requirements.

- Easy Programming: Programming a three-axis CNC is straightforward. Simple modifications to the program are sufficient to modify the component.

What Is a 5-Axis CNC?

Machining operations are carried out along five axes of motion by a 5-axis CNC machine. It rotates about the other two axes (A and B) and can motion along the three linear axes (X, Y, and Z). The increased range of motion facilitates the generation of complex geometries by the machine.

What Can a 5-Axis CNC Do?

A 5-axis CNC can produce geometries that require numerous angles and contours. The ability to rotate the cutting instrument along five axes results in parts with more precise details and smoother surfaces. Continuous milling is an additional capability of a 5-axis CNC machine. This feature allows the cutting tool to track the curvature of the material, resulting in reduced traces and steps.

Components such as turbine blades, aerospace elements, and molds can be manufactured with a 5-axis CNC machine. In the aerospace industry, for instance, it is utilized to create intricate designs for aircraft engine components. Additionally, the 5-axis capability is crucial for prosthetics and medical implants.

What Are the Advantages of 5-Axis CNC?

The benefits of 5-axis CNC machines are as follows:

- CNC machining with five axes can handle workpieces with very complicated geometries.

- Five distinct workpiece areas may be machined simultaneously in a single configuration.

- Production rates are very rapid due to the decreased amount of setups.

- 5. Axis CNC machining allows for the creation of components with high accuracy.

- Flexibility: 5-axis machines can make a broad range of shapes and components.

What Is the Difference Between 3-axis and 5-axis CNC?

One key difference between 3-axis and 5-axis CNCs is the number of axes along which the cutting tool may be oriented and moved. A three-axis computer numerical control machine can move its cutting tool in all three directions. Instead, the cutting tool of a 5-axis machine may be moved along the X, Y, Z, A, and B axes.

Another distinction between the two is the cost of the machine. Buying, programming, and operating the 3-axis model is much less expensive than the other one. Because of this, the price per component is often less as well.

Another critical differentiator is the simplicity of generating and working with complicated forms. Deep cuts may be achieved with 5-axis machines, even in complex geometries. Increased output is possible since you don’t have to turn the workpiece by hand to access its surfaces. However, for a 3-axis machine to cut complicated geometries, it is necessary to make many changes.

Summary

Whether you need a 3-axis or 5-axis CNC machine is more important than whether one is inherently superior; the focus should be on your requirements. Both machines have advantages, so choosing one depends on project type, money, and available workforce. You can go right with either a 3-axis or 5-axis CNC machine when it comes to improving the accuracy and efficiency of your production process.